See our machinery in action in 2025: IFFA- Frankfurt am Main, May 3–8 | IPACK-IMA - Milan, May 27–30.

Please be informed that our company will be closed for the Easter holidays on the following days: Friday, April 18th, 2025 – Good Friday // Monday, April 21st, 2025 – Easter Monday.

We will resume regular operations on Tuesday, April 22nd, 2025.

RELATED PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

A single source provider of flexible packaging and rigid tray packaging solutions, ProMach serves a variety of industries and applications. With numerous machinery installations worldwide and a vast portfolio of rugged and proven solutions, ProMach offers extensive experience handling a wide range of products in diverse conditions. ProMach consults with customers to identify the ideal package type to fit their unique application for each project, giving customers both choice and flexibility. Many of the world’s most successful brands use ProMach solutions to package their products into bags, pouches, sachets, stickpacks, trays, and more.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

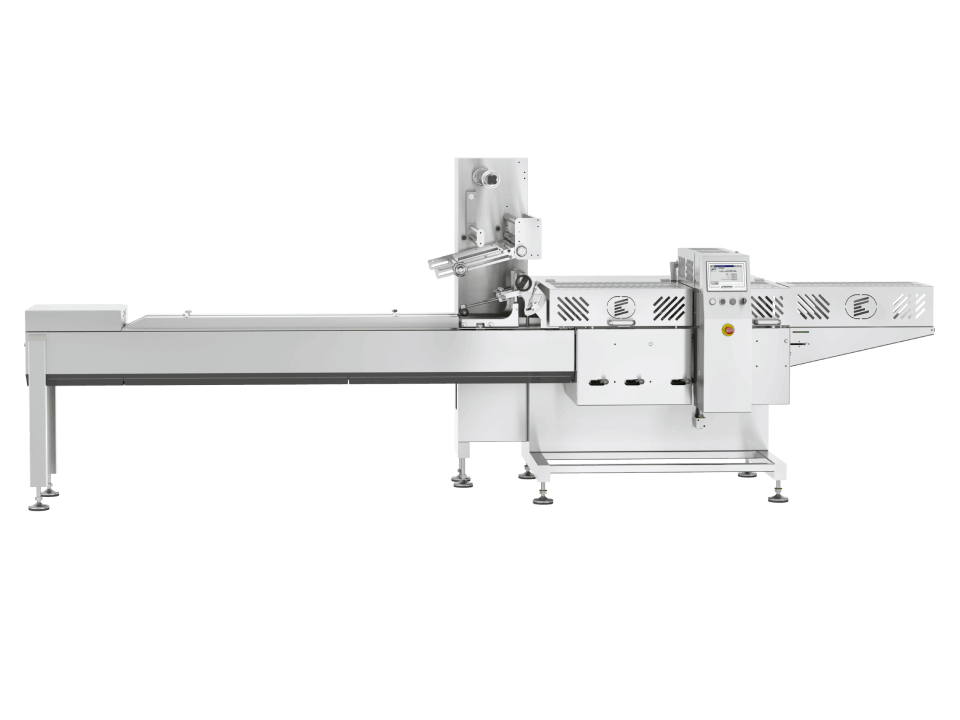

learn moreREEPACK BOX MOTION FLOW WRAP PACKAGING MACHINE MODELS

- ReeFlow 300

- ReeFlow 300B

- ReeFlow 300W

- ReeFlow 300WB

-

Stainless Steel Construction

-

Modified Atmosphere Packaging (MAP)

-

Cantilevered Frame

-

Store Up to 100 Different Programs on PLC

-

Coding Unit

-

Misplaced Product Detection

-

Longitudinal Sealing Re-fill and Trimming

-

Flow Bag

-

Gusseting Device

-

Deflating Pressure Pad

-

Gas Flush, Mix, & Analyzer

-

Quality Control with Reject System

-

Left Hand Version

-

Flat Belt Infeed / Multi-belt Feeder

-

Fully Automatic Adjustments Per Saved Recipe

-

Double Reel Holder with Auto-splice